- Home

- »

- BATTERY MODULE & PACK

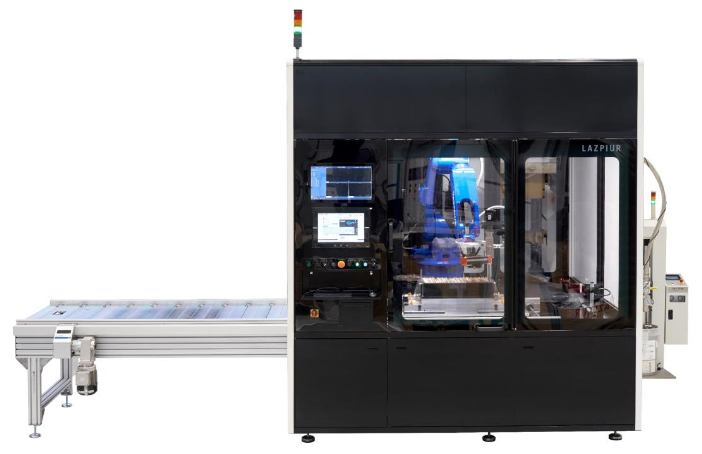

FLEXIBLE, HIGH CAPACITY BATTERY MODULE & PACK ASSEMBLY LINES FOR E-POWERTRAIN

Our turnkey test and assembly installations offer the optimal, most cost-effective solution for the most demanding of clients.

DESCRIPTION

We provide specialised manufacturing solutions for battery production. Our core expertise is the knowledge of processes such as handling, assembly, soldering, bonding and testing of EV battery packs and modules. Lazpiur is particularly specialised in the issue of scalability in relation to variable volume scenarios.

DETAILS

- Incorporating “Flex Line AIR” technology, for multi-product installations.

- Modules and Battery Pack Assembly.

- Annual production capacity of up to 350,000 modules.

- Automatic and semi-automatic lines.

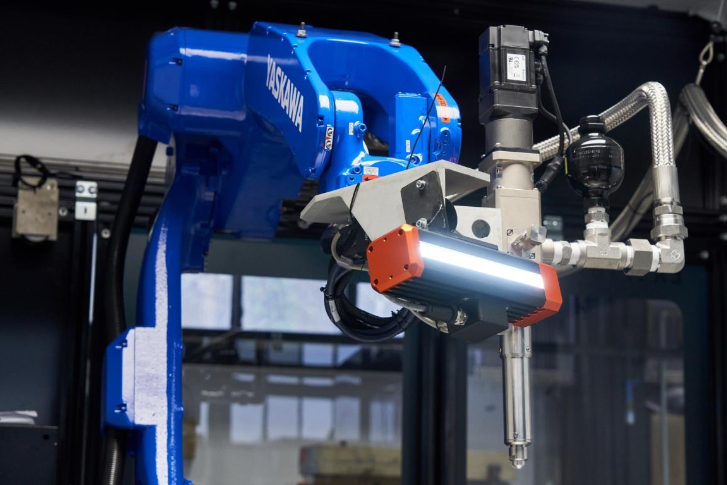

- Utilising Lazpiur’s own 3D Vision technology for inspection and quality control.

- Automatic soldering.

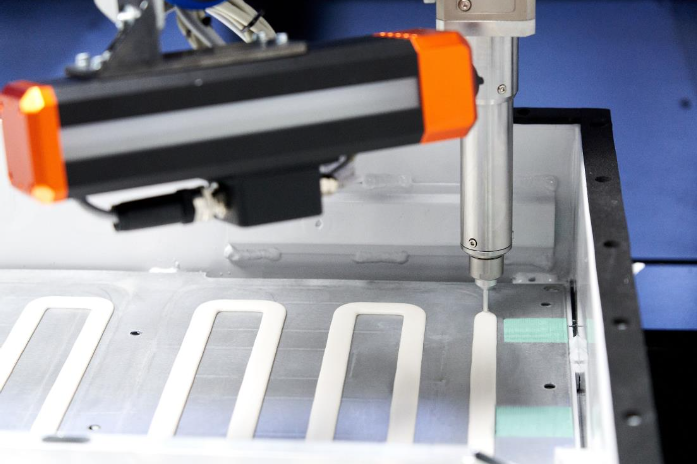

- Dispensing technology.

- Automatic Screwdriving systems.

- Auto-stacking.

- Force measurement control.

- Marking (laser, ink, etc.).

- Option to integrate Automatic Storage.

- Defect Management.

- Integration of Traceability Control into factory protocol.