- Home

- »

- X-RAY & CT TECHNOLOGY FOR BATTERY CELL MANUFACTURING

X-RAY & CT TECHNOLOGY FOR BATTERY CELL MANUFACTURING

Lazpiur and ARRAY provide a comprehensive distribution and integration service, covering the entire process from technical pre-project engineering to installation and full production commissioning of X-ray inspection systems in Europe.

DESCRIPTION

This end-to-end approach ensures that each customer receives customized, turnkey solutions, including feasibility analysis, technical adaptation, installation, calibration, and operator training, guaranteeing optimal performance and seamless integration into their production lines.

INFORMATION

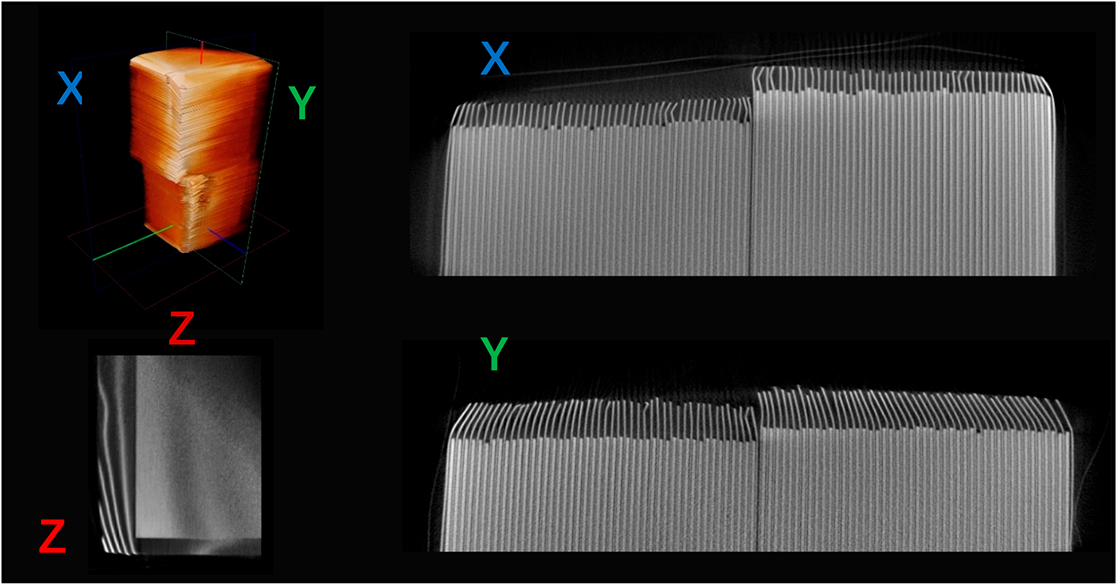

- Inline CT

- Detection rate: 2-60PPM (single CT station rate 6ppm/12PPM)

- High image resolution: 20-30um

- Uses low-dose fast scanning, single corner scanning time 3~6 seconds

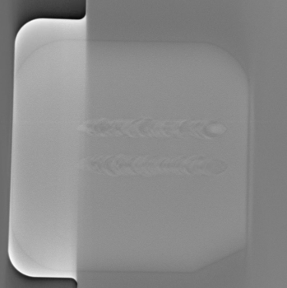

- The auto Overhang detection using AI algorithm, reaching a measured GRR of less than 15%

- Over kill: Actual landing statistics around 0.5%

- X-ray source and detector rotate while battery placed horizontally, to protect battery and avoid damage.Standard solution that can fit with an existing machine or in a new one.

- Offline Multifunctional CT

- Detection rate: 1-6PPM

- Image resolution: 20-30um

- Automatic switch between corners, with automatic identification

- Compatible with multiple types of batteries:

- Winding, stacking, 4680 cylindrical, and cased cells

- Capable of accommodating multiple test items:

- Stacked cell OH, tab welding, tap breakage, electrode/tab folding, foreign objects

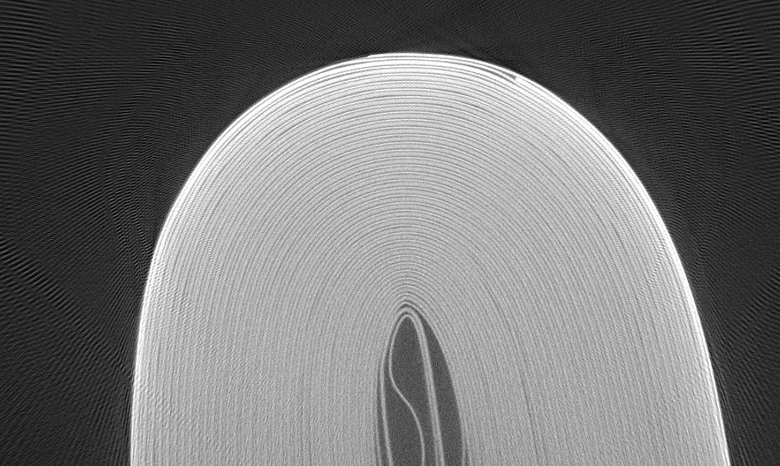

- Offline Standard CT

- High-resolution, up to 4um, suitable for laboratory precision measurements using a 225KV high-voltage X-ray source with strong penetration capability for module and large cell measurements.

- Equipped with a high-speed, large-area detector measuring 430 x 430mm, meeting diverse testing requirements.

- X-ray source, detector, and turntable are all movable, compatible with spiral scanning.

- Extra-large chamber, compatible with samples up to Φ800 x 1000mm in size.

- Turntable load capacity greater than 50KG, compatible with most modules.

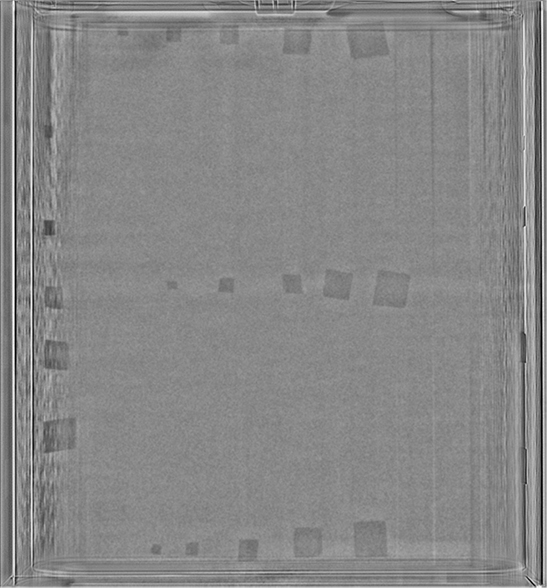

- Inline X-RAY

- Advantages & Features

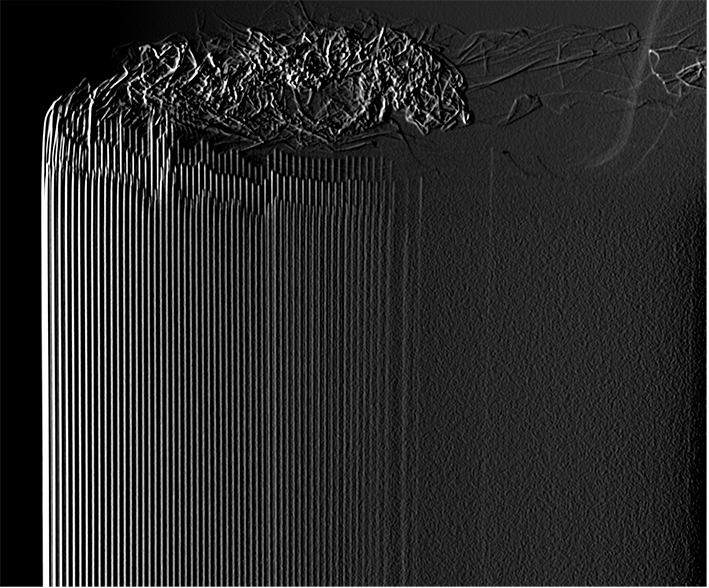

- Image acquisition capability: Customized detector with higher sensitivity and lower signal noise ratio.

- Image processing capability: Capable of processing and enhancing 1‰ grayscale difference, presenting clear images.

- AI recognition capability: Accumulated 10 months of training, capable of identifying various abnormal shapes.

- Detection capability

- Se pueden detectar los residuos y las piezas dañadas del electrodo negativo.

- Negative electrode piece residue can be detected, negative electrode piece damaged.

- Battery cell specifications: 50mm thick, with casing, injected electrolyte.

- Negative electrode tab insertion can be detected, battery cell thickness 30mm.

- Metal particle size detected: 0.3*0.3mm.

- Advantages & Features