- Home

- »

- X-RAY & CT TECHNOLOGY FOR SMT MANUFACTURING LINES

X-RAY & CT TECHNOLOGY FOR SMT MANUFACTURING LINES

Lazpiur and ARRAY provide a comprehensive distribution and integration service, covering the entire process from testing, technical pre-project engineering to installation and full production commissioning of X-ray & CT inspection systems in Electronic Industry for SMT Lines.

DESCRIPTION

This end-to-end approach ensures that each customer receives customized, turnkey solutions, including feasibility analysis with real testing, certification, technical adaptation, installation, calibration, and operator training, guaranteeing optimal performance and seamless integration into their welding and adhesive lines.

INFORMATION

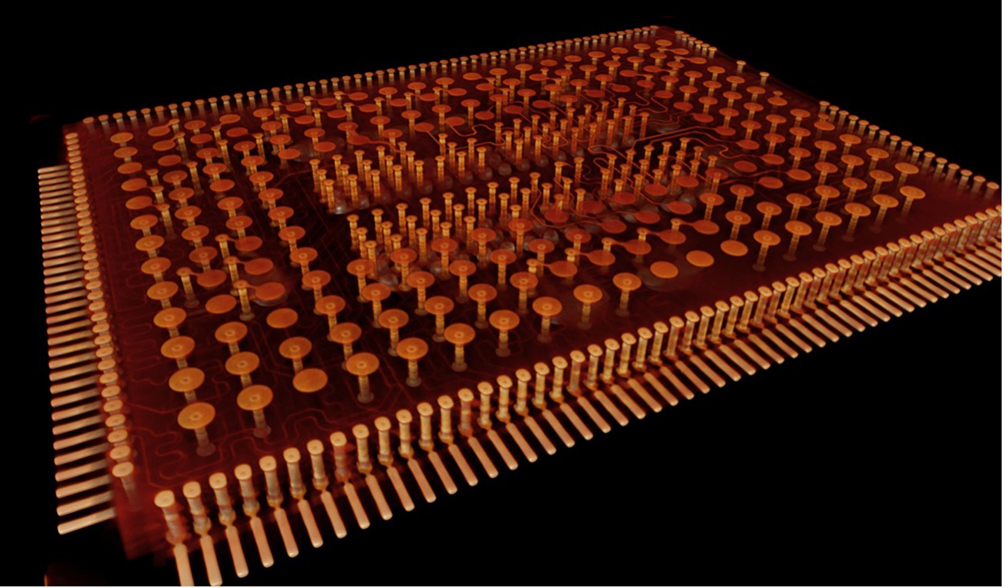

- INLINE X-Ray

- Detection rate: 5-20PPM

- Image resolution: 20-30um

- Automatic switch between corners, with automatic identification

- Compatible with multiple types of PCBs

- Capable for welding quality inspection

Applications

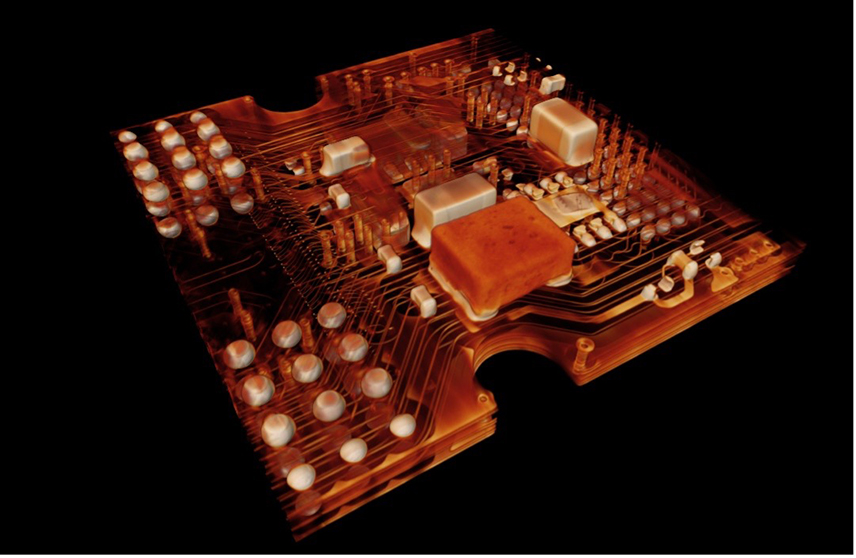

- BGA/CSP, through-hole components, SOP/QFP, transistors, R/C chips, bottom-electrode devices, QFN, power modules, POP

- Defects Detected: Voids, open solders, solder volume, misalignment, bridging, through-hole fill, solder balls.

Key Features & Advantages

- Resolution Options (μm/px): 3, 6, 8, 10, 15, 20, 25, 30

- AI-Enhanced Algorithm: Accurately identifies defects, distinguishes noise from actual anomalies (e.g., voids), and supports human decision-making

- Multi-Mode Imaging: Single sample placement enables 2D/3D inspection of any region

- High-Res Large-Area Auto Scanning

- Dual Mode (Precision + Fast): Fastest imaging speed of 2 seconds per area